Large regions of Ethiopia are ideal for cotton cultivation. In some cases, long-stack qualities are obtained. For years, the government has been making plans to increase volumes and expand areas. So far, it has not been possible to sustainably increase yields and to reconcile them with industrial policy in the textile sector. What to do?

Ethiopia is, in fact, a cotton country. Cotton has always been the raw material for the typical hand-woven clothing. The climatic conditions are good, the soils are suitable and there is enough agricultural labour. Ethiopia has also long had a full-fledged textile and clothing industry. The country is in the starting blocks to greatly expand the production and further processing of cotton. But exports are stalling and domestic demand is weakening. What’s wrong?

The situation

Indeed, the Ethiopian government is relying more on cheap ready-to-wear services than on strengthening existing potential. This is understandable in view of the young and rapidly growing population. However, the traditional value chain and manufacturing know-how are at risk as a result. Foreign exchange management makes it difficult for industry to procure fibres abroad. The cotton farmers, on the other hand, are not under the aegis of the Ministry of Agriculture, but are “managed” by the Ministry of Trade and Industry. There are no agricultural programmes for competing crops such as peanuts or coffee for cotton. Margins are lower for cotton cultivation – making wages less attractive to field workers. As a result, many farmers are switching to other seeds.

The problems

So far, the cotton farmers are safe to sell domestically. Ethiopian spinning mills depend on the local fibre. And this is being exploited: the prices are high, the quality below average. This is not due to the fibres themselves. They have standard, sometimes even very good quality. However, Ethiopian cotton is usually heavily polluted with plant residues, after picking by hand and also after ginning. Due to a lack of manpower, the harvest often drags on for too long. Plastic cords, bags and tarpaulins during transport also contribute to contamination. The ginning plants are often far away from the farms, and there is often a lack of spare parts. In the end, this leads to products that cannot be marketed internationally. Domestically, cheap Asian textiles have long been on the rise.

PartnerAfrica Ethiopia seeks solutions

As part of the cooperation project of ETGAMA and Gesamtmasche, a pilot trial with several Ethiopian companies in the cotton value chain is launched in cooperation. The aim is to increase quality and transparency already in the cotton season 2020/21. Even simple measures can make a big difference. A remuneration system for farmers and workers, which is more oriented towards the quality and not only on the weight of the harvest, is one of the keys. Replacing plastic during transport with cotton bags and tarpaulins can also make a major contribution. The transparency of the chain from the field to the ginnery and to the spinning mill and finally to further processing stages helps to promote quality work. This in turn opens doors to an international clientele.

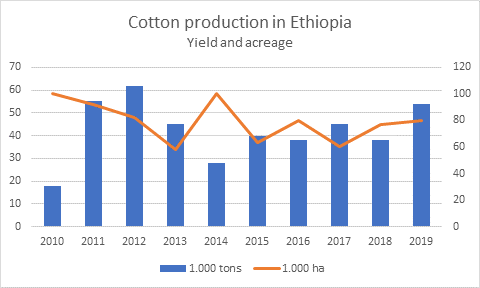

Source: US Department of Agriculture

Cotton from different farms in the laboratory of the Adama spinning mill.