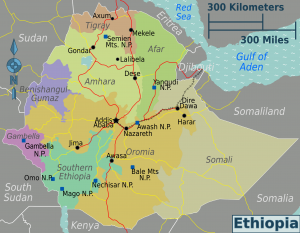

Ethiopia’s Regions. © Peter Fitzgerald, CC BY-SA 3.0 via Wikimedia Commons

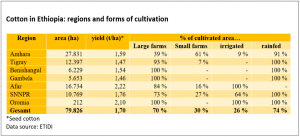

Today, cotton is grown mainly in six regions: Amhara, Afar, Tigray, SNNPR (Southern Nations, Nationalities, and Peoples’ Region), Benishangul-Gumaz and Gambela. Ethiopia’s traditional textile chain is characterized by vertically integrated companies that process locally grown cotton. There are currently 16 active spinning plants, which together have a processing capacity of more than 100,000 tonnes of cotton per year. At present, capacity utilization is around 50 percent.

Diverse challenges

The cotton sector is struggling with quality problems and outdated ginning plants. The harvest year 2020/21 was also under a bad star several times: in addition to the global corona pandemic, Ethiopia was hit by the worst locust plague in decades. Floods damaged or destroyed about a third of the harvest. In addition, there are unrest in the Tigray region.

Hardly any pesticides and fertilizers

Amhara region: protecting cotton from birds.

Tigray, Dansha SHF: Molasses traps to protect cotton from ballworms.

Today, most of the cotton is still produced conventionally. But certified qualities, especially BCI Cotton, are on the rise. The northern regions of Tigray and Amhara are the leading regions, as well as the southern Bana Tsemay (SNNPR). But even without a certificate, farmers hardly rely on chemistry. For many, it is simply too expensive. “Most regions still do not use fertilizer,” says Mesele Mekuria, Cotton Inspection Director at the Ethiopian Textile Industry Development Institute (ETIDI).

“Even with simple measures, noticeable quality improvements can be achieved,” says Mesele Mekuria. “Training for a more professional hand picking, more prudence in transport and the absence of plastic when binding and packaging would already make a big difference.”

Photo: ETIDI

Afar Region: Yasin-Mohamed Farm.

20 farms under the microscope

During the 2020/21 cotton harvest, the renowned cotton expert mapped the growing areas in the regions for the Partner Africa project of GESAMTMASCHE and the Ethiopian textile association ETGAMA – not only according to farms, areas and expected yields, but also according to existing certifications and important quality parameters. From large farmers to smallholder cooperatives, a wide range of players are on board.

smallholder cooperatives, a wide range of players are on board.

For better quality and transparency

The study should not only be a prerequisite for quality improvements and a better interplay of the textile chain. It is also an important element in the development of a transparent production chain. More than 20 companies from the cotton processing industry have already expressed their interest in the pilot project.

Pan-African cooperation: The first sample shipment of Senegalese cotton has arrived at Adama Spinning. Ageazi Hailemariam, Managing Director of ETIDI, was able to examine raw material and processing with representatives of five other spinning companies. A total of eight companies want to participate. The domestic supply is scarce this year and the trash content in Senegalese cotton is much lower.

Photo: ETGAMA

Cotton from Senegal

Due to the poor harvest, the Ethiopian spinning mills lack raw material. The foreign exchange restriction makes access to foreign fibres difficult for cotton processors. GESAMTMASCHE and ETGAMA are therefore pushing ahead with an experiment: 25 tons of certified cotton from Senegal is brought to Ethiopia and processed by five spinning mills to different yarn qualities. It is hoped that the systematic comparison with domestic fibre will make progress in national standards.

South Friel Farm: picking payment is based on weight.

Packing seed cotton on the farm.

Gambela Region: Haile Farm.

Photo (Title): Solen Feyissa – pixabay.com